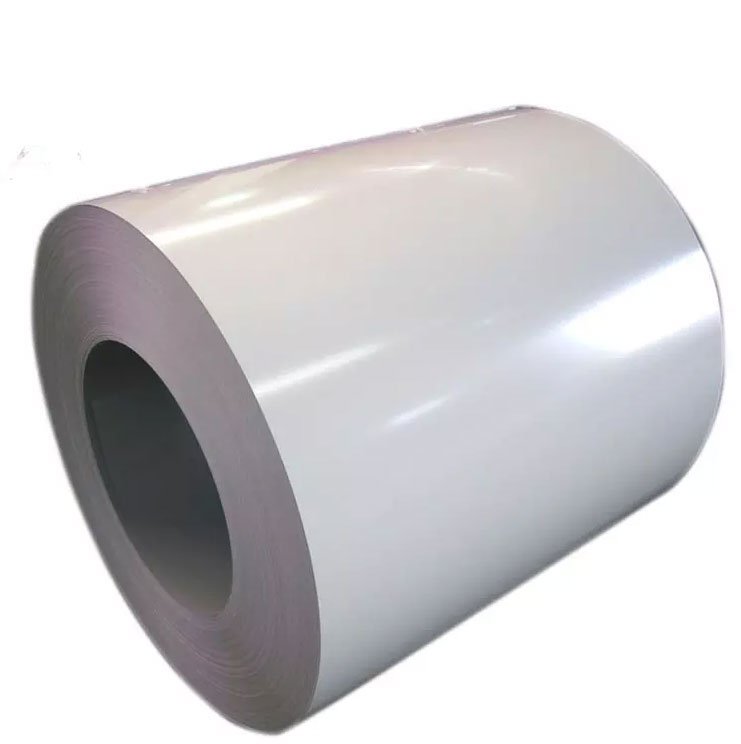

Color coated aluminum coil is a popular and versatile material used in various industries due to its aesthetic appeal and functional properties. It is widely utilized in construction, automotive, and manufacturing sectors for its durability and longevity. The color coating on the aluminum surface not only enhances its visual appearance but also provides a protective layer against environmental elements, ensuring its extended lifespan. In this essay, we will delve into the factors that contribute to the durability and longevity of color coated aluminum coil.

One of the primary reasons for the durability of color coated aluminum coil is its exceptional corrosion resistance. Aluminum naturally forms a thin oxide layer on its surface, which acts as a barrier against corrosion. However, the color coating further enhances this protection by providing an additional layer of defense. The coating is typically composed of various resins and additives that create a robust shield against moisture, UV radiation, chemicals, and atmospheric pollutants. This protective layer prevents the aluminum coil from oxidation, thus prolonging its lifespan.

Moreover, color coated aluminum coils undergo a rigorous pre-treatment process before the application of the coating. This process involves cleaning, rinsing, and chemical treatment of the aluminum surface to remove any impurities, oils, or oxides. By eliminating these contaminants, the adhesion of the subsequent coating is significantly improved, ensuring a long-lasting bond between the aluminum substrate and the color layer.

The color coating itself plays a vital role in the durability of the aluminum coil. It is typically composed of high-quality pigments, resins, and binders that are specifically formulated to withstand harsh environmental conditions. These coatings are engineered to provide excellent resistance to fading, chalking, and color change over time. The pigments used are often inorganic, such as ceramic or metallic pigments, which offer superior color stability and resistance to UV radiation. This enables the color coated aluminum coil to maintain its vibrant appearance for an extended period, even when exposed to sunlight and other weathering elements.

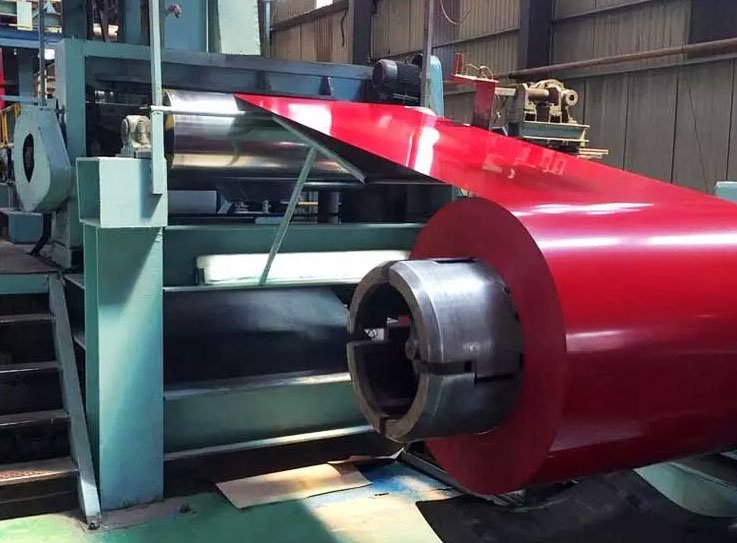

Furthermore, the color coating on aluminum coil is generally applied through a continuous coil coating process. This process ensures uniform coverage and thickness of the coating, eliminating any potential weak spots or inconsistencies. The coated aluminum coil undergoes curing at high temperatures, which enhances the adhesion and durability of the coating. This manufacturing technique results in a highly durable and long-lasting product, capable of withstanding mechanical stresses, temperature fluctuations, and other external factors.

The versatility of color coated aluminum coil also contributes to its longevity. It can be shaped, bent, and formed into various profiles and designs without compromising its protective coating. This flexibility allows for its applications in a wide range of industries, including roofing, cladding, signage, and interior decoration. The ability to customize the color, gloss, and texture of the coating further enhances its aesthetic appeal and longevity, as it can be tailored to meet specific design requirements.

In conclusion, the durability and longevity of color coated aluminum coil make it a preferred choice for many industries. Its exceptional corrosion resistance, rigorous pre-treatment process, high-quality color coating, and continuous coil coating application contribute to its long lifespan. The ability to withstand environmental factors, maintain color stability, and resist fading ensures that the aluminum coil retains its visual appeal and protective properties for years to come. Whether in construction, automotive, or manufacturing, color coated aluminum coil proves to be a reliable and durable material that delivers both functionality and aesthetic value.